Mitsubishi Electric Develops Teaching-less Robot System Technology

By : Nata Kesuma | Tuesday, March 29 2022 - 14:30 IWST

Mitsubishi Electric Corporation, Robot System Technology

INDUSTRY.co.id - TOKYO – Mitsubishi Electric Corporation (TOKYO: 6503) announced today it has developed a teaching-less robot system technology to enable robots to perform tasks, such as sorting and arrangement as fast as humans without having to be taught by specialists.

The system incorporates Mitsubishi Electric’s Maisart® AI technologies including high-precision speech recognition, which allows operators to issue voice instructions to initiate work tasks and then fine-tune robot movements as required.

The technology is expected to be applied in facilities such as food-processing factories where items change frequently, which

has made it difficult until now to introduce robots.

Mitsubishi Electric aims to commercialize the technology in or after 2023 following further performance enhancements and extensive verifications.

Product Features

1) Robot movements self-programmed/adjusted based on simple commands from operator

- Robot movements are self-programmed and self-adjusted in response to simple commands communicated

by voice or via a device menu by a non-specialist operator.

- Proprietary voice-recognition AI accurately recognizes voice instructions even in noisy environments for

the first time in industrial robot manufacturers.

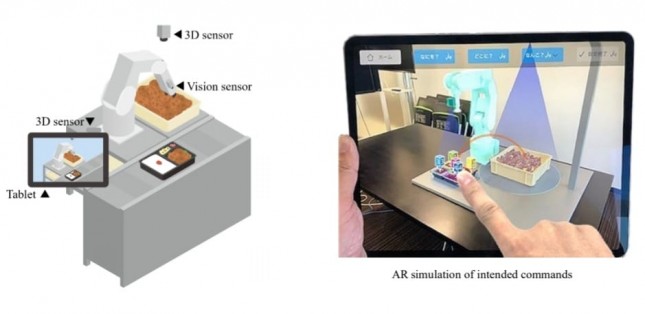

- Sensors detect 3D information (images and distances) about work area, which are processed with

augmented reality (AR) technology for simulations that allow operator to visualize expected results.

- Programming and adjustments require just one-tenth or less time than conventional systems.

Mitsubishi Electric survey of instruction systems deployed by industrial robot manufacturers (as of February 28, 2022) In-house comparisonThe system, responding to voice or menu instructions, scans the work surroundings with a three-dimensional

sensor and then automatically programs the robot’s movements. Movements can be easily fine-tuned via

further commands from the operator.

Mitsubishi Electric’s unique voice-recognition AI, highly accurate even in noisy factories, offers the first voice-instruction user interface deployed by industrial robot manufacturers.

For example, in a food-processing factory, a non-specialist could instruct a robot simply by saying something like "Pack three pieces of chicken in the first section of the lunch box." The AI can infer implied meanings if a voice instruction is ambiguous, such as determining how much motion compensation is required if instructed "A little more to the right."

Alternatively, a tablet equipped with menus can be used to issue instructions or to select categories such as “where,” “what” and “how many” to generate simple programs.

The tablet also can be used to view stereographic AR simulations that allow the operator to confirm that instructions will have the intended results. For added convenience, the system also can recommend the ideal positioning of a robot in an AR virtual space without requiring a dedicated marker, another industry first.

By enabling the self-programming of robot movements, including obstacle avoidance, and the system reduces the workload associated with gathering environmental information, inputting data and confirming operations using simulators and/or actual equipment.

As a result, the system can complete these cumulative processes in just one-tenth or less time compared to conventional methods. In view of such advantages, the system is expected to support the automation of work sites that are not readily suited to robots, such as food-processing.

2) Technology-optimized movements enable robot to perform tasks as fast as humans

- The self-programming system generates commands to control robot movements, including to avoid

obstacles, in order to perform work tasks as fast as humans (minimum 2 seconds to grasp item5).

- The system also adjusts and optimizes the timing of opening and closing robotic hands to reduce

wasted time.

- Using visual information from a camera attached to the robot’s hand, the system automatically corrects

movements, including when the position of the robot or the object to be placed changes.

Time required to grasp and place a part in a designated place Conventionally, increasing a robot's operational speed requires time to realize the desired trajectories because the operator must use a simulator and/or the actual robot to determine the best conditions. In response, Mitsubishi Electric has developed a trajectory-generation technology to optimize robot movements using

information about surrounding obstacles and robot performance.

The company has also developed an acceleration/deceleration-optimization technology that automatically generates a velocity pattern to achieve the shortest possible arm-travel time within the permissible range of force that can be exerted by the robot.

Both technologies help to shorten the time required to adjust the robot’s movements. Optimizing the timing of hand opening/closing also helps to reduce work time. Conventionally, such adjustments are performed manually using simulations and operating the robot.

The new technology. however, automatically adjusts and optimizes this timing according to the characteristics of the hand and the object to be grasped, thereby eliminating lengthy manual adjustments while also improving work efficiency.

In addition, the grasping-recognition AI and a three-dimensional sensor fixed above the system quickly determine the best position for grasping, thereby reducing wasted time. Furthermore, visual information from a camera attached to the robot hand allows the robot to self-correct its movement if the position of the robot or the target object shifts.

By optimizing robotic arm and hand movements, Mitsubishi Electric’s new technology enables robots to work as fast as humans, i.e., a minimum 2 seconds to grasp an item and place it in a designated place.

Other Features

Integrated system management of peripheral information To simplify the process of adding custom functions, the system supports the Robot Operating System (ROS) software platform.

Also, Mitsubishi Electric has developed a ROS-Edgecross linkage function to centrally manage information on Edgecross, ROS and the entire system. Edgecross connectivity and multi-vendor capability simplify the monitoring and analysis of entire production lines for enhanced productivity and quality.

Japan-based open software platform for edge computing combining FA and IT.

About Maisart

Maisart encompasses Mitsubishi Electric’s proprietary artificial intelligence (AI) technology, including its compact AI, automated-design deep-learning algorithm and extra-efficient smart-learning AI. Maisart is an abbreviation for "Mitsubishi Electric's AI creates the State-of-the-ART in technology."

Under the corporate axiom "Original AI technology makes everything smart," the company is leveraging original AI technology

and edge computing to make devices smarter and life more secure, intuitive and convenient.

Maisart is a registered trademark of Mitsubishi Electric Corporation.

About Mitsubishi Electric

Mitsubishi Electric Corporation

With 100 years of experience in providing reliable, high-quality products, Mitsubishi Electric Corporation

(TOKYO: 6503) is a recognized world leader in the manufacture, marketing and sales of electrical and

electronic equipment used in information processing and communications, space development and satellite

communications, consumer electronics, industrial technology, energy, transportation and building equipment.

Mitsubishi Electric enriches society with technology in the spirit of its “Changes for the Better.” The company

recorded a revenue of 4,191.4 billion yen (U.S.$ 37.8 billion*) in the fiscal year ended March 31, 2021. For

more information, please visit www.MitsubishiElectric.com

*U.S. dollar amounts are translated from yen at the rate of ¥111=U.S.$1, the approximate rate on the Tokyo

Foreign Exchange Market on March 31, 2021

Read Also

MoreLogin, the World's #1 Antidetect Browser, Showcased at Affiliate…

Experts gather in Nanning to support high-quality development of…

Huawei Garners Award from Manpower Ministry as Best Foreign Enterprise…

Government's Role in Consumer Protection in the Digital Era

Huawei Supplier Convention 2023: Driving Collaboration and Innovation…

Today's Industry

Rabu, 28 Februari 2024 - 12:47 WIB

Carsurin and NBRI Strengthen Strategic Alliance to Propel Indonesia’s EV Industry

PT Carsurin Tbk ("Carsurin") and the National Battery Research Institute ("NBRI") are pleased to announce the signing of a pivotal Strategic Alliance Agreement (SAA), marking a significant advancement…

Rabu, 21 Februari 2024 - 08:43 WIB

Gov’t to Continue Disbursing Rice Assistance

President Joko “Jokowi” Widodo has ensured that the Government will continue rolling out the rice assistance program for low-income families. The President made the statement when handing…

Rabu, 21 Februari 2024 - 08:40 WIB

Bapanas Head Ensures Availability of Rice Stock Ahead of Ramadan

The National Food Agency (Bapanas) has ensured the availability of rice for the fasting month of Ramadan and Eid al-Fitr 1445 Hijri/2024 CE. “We believe that there is enough rice for the fasting…

Rabu, 21 Februari 2024 - 08:23 WIB

Receives Chairman of Jababeka (KIJA), Menpora Dito Ready to Support the Development of Sports SEZs

Chairman of PT Jababeka Tbk (KIJA), Setyono Djuandi Darmono met the Minister of Youth and Sports of the Republic of Indonesia (Menpora RI) Dito Ariotedjo at the Kemenpora RI Office, Senayan,…

Senin, 19 Februari 2024 - 17:39 WIB

The Indonesian Embassy in Cairo Receives Aid for Palestine

The Indonesian Embassy in Cairo welcomes the Radjiman Wedyodiningrat Warship (RJW-992) which arrived at the Al Arish Port, North Sinai Province of Egypt at 8.00 A.M. Cairo local time (13/02).…

News Comment